In addition to the chip, the peripheral component of the RFID tag is only the antenna. However, the importance of the antenna part is often overlooked. People will find that the antenna has become the biggest obstacle in the application after the chip is designed. Because the matching problem between the chip and the antenna was not considered from the beginning, and this determines whether the tag can work well and how far the working distance is. Therefore, to make the RFID tag that meets the requirements, the design of the antenna should be synchronized with the technology of the chip and need to cooperate with each other.

At present, the manufacturing methods of RFID antenna include copper foil or aluminum foil etching, copper wire winding (generally applicable to low frequency and high frequency), electroplating, printing, etc.

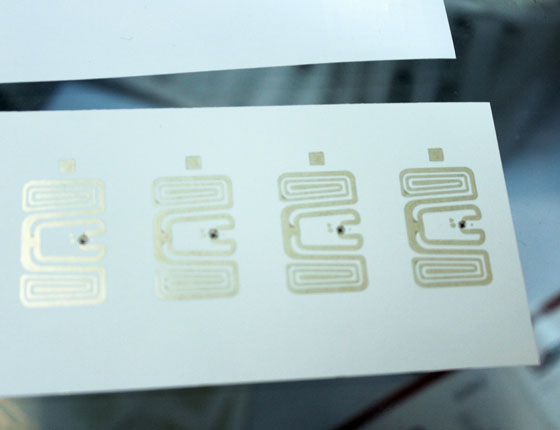

1) Etching, include aluminum foil and copper foil etching

It is the most mature and widely use method for rfid antenna, and The antenna produced by etching technology can be used in HF and UHF. The advantages is low resistivity, good weather resistance, and stable signal.

2) opper wire winding

Using the coil winding method, the coil is wound and fixed on the winding tool, and a certain number of turns is wound according to different frequency requirements. The manufacture of this antenna is mainly used for low-frequency 125-134KMHZ and high-frequency 13.56MHZ tags, and is rarely used in UHF. Its advantage is showing good performance when the antenna area or volume is small. But its disadvantages are low production efficiency, high cost, high product thickness, and not resistant to bending.

3) Printing

The printed antenna directly uses conductive ink (carbon paste, copper paste, silver paste, etc.) to print conductive lines on an insulating substrate (or film), and form the antenna circuit. The main printing method has expanded from only using screen printing to offset printing, flexographic printing, gravure printing and other production methods. It is characterized by fast production speed, but due to the large resistance of the circuit formed by conductive ink, its application range is limited to a certain extent.

RFID tag antenna manufacturing development trends

With the rapid development of RFID technology, it has also promoted the development of RFID tag antennas. RFID tag antennas are becoming more and more diversified. At present, electronic tag antennas are mainly moving in the way of environmental protection, anti-counterfeiting and anti-transfer, and diversification of raw materials. And the advantage of low cost is becoming more and more obvious.

X Request a Quote

Copyright © Shenzhen Colorful Smart Tech Co., Ltd. All Rights Reserved | Sitemap | XML | Privacy Policy